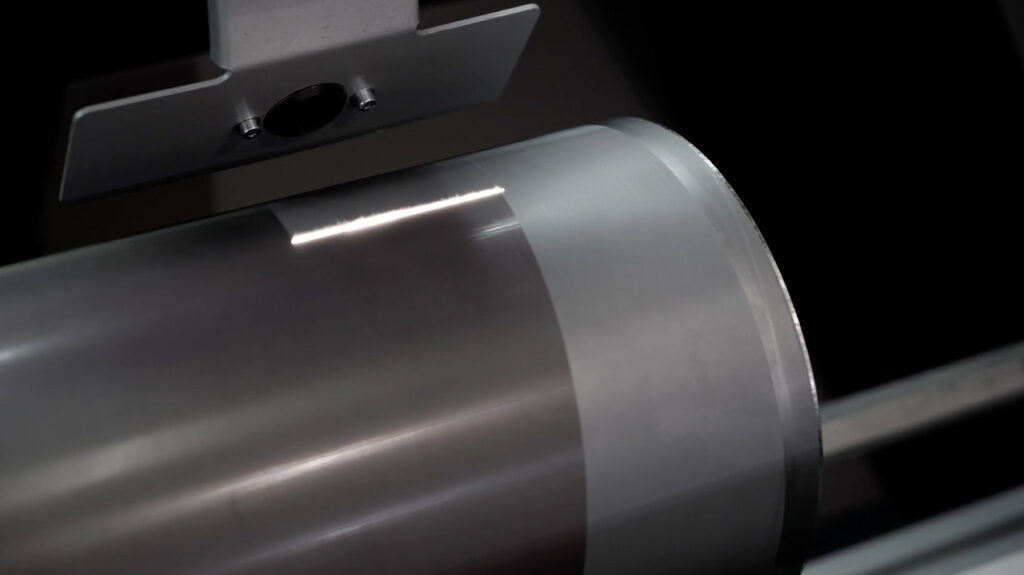

Eco-friendly laser cleaning service

Through our business partnership with Spanish company TEG Technologies, Watanabe Gosando is proud to offer a state-of-the-art laser cleaning service for your anilox rolls and gravure print cylinders.

This cleaning service uses the environmentally friendly SITEXCO laser cleaning machine. (Max roll length 1,500mm)

Additionally, as a Japanese distributor of TEG Technologies, we also offer the SITEXCO system for sale to those customers with frequent anilox or gravure cylinder cleaning needs. (There are four models that can accept rolls between 850mm and 3,250mm)

●Line-up

| SNP 1.0 | SLP 1.5 | SLP 2.5 | SLP 3.2 | |

| Max roll length | 850mm | 1,500mm | 2,500mm | 3,250mm |

| Shaft diameter (min/max) | 45mm/135mm | 80mm/300mm | 80mm/300mm | 80mm/300mm |

| Max roll weight | 80kg | 200kg | 250kg | 300kg |

| Max # of rolls | 1 roll | 1 roll | 2 rolls | 2 rolls |

| Machine dimensions (mm) | 1,600×670×1,600 | 2,450×835×1,750 | 3,450×835×1,750 | 4,150×835×1,750 |

Use cases

- As the ink supply source in flexographic printing, the anilox roll has a critical role in the effective operation of your printing machine! If the anilox’s cells become clogged with old ink then the correct amount of fresh ink cannot be supplied, causing numerous possible print defects.

- Gravure print cylinders are traditionally cleaned using a variety of liquid cleaning agents, however with the use of the SITEXCO laser cleaner you can clean your cylinders with no waste and no fuss.

- Laminating machines apply adhesive laminate using a metal mesh roll that’s labor intensive and time consuming to clean. By using the SITEXCO laser cleaner you can reduce not only the cleaning time but also your environmental impact.

Cleaning method

The cleaning method is very simple.

- After placing the roll in the machine and entering the length and diameter on the input screen, the autofocus will adjust the laser to the proper height for safe effective cleaning.

- Four levels of cleaning routine allow you to choose the right intensity for your roll’s material and level of contamination. Perform both gentle regular cleanings and more detailed deep cleanses with ease and with no risk of damage!

- The cleaning targets for this system are easily removable sleeve shaped rolls, as well as those narrow web rolls (with shafts) which can be easily carried.

- Large anilox rolls, such as those used in large direct printing corrugated machines, are outside the scope of this machine.

Features

- Since the SITEXCO is a laser-based cleaning system, it requires no physical cleaning agents and generates no waste.

- Ink dried on the anilox is sublimated by the laser and then sucked into a vacuum hose mounted within the machine.

- The internal vacuum system then sucks this ink particulate to an externally accessible filter module.

- No gases or ink particles escape the machine, so it is safe to use indoors in enclosed spaces.

- Total work time, including both set-up and cleaning, is usually around 10 minutes per roll.

- [Power Saving Design!] The power cost per anilox roll averages around \30 a roll!

- The shutters must be shut before the machine will begin cleaning and the laser will not function if the door is open, preventing accidental laser exposure.

- The safety-first design requires no human contact other than inserting and removing the roll.

- Although its robust design makes problems unlikely, the machine comes equipped with IoT connectivity so that it can instantly alert you to any mechanical troubles. Spare machines, parts, and trained technicians are also available domestically within Japan to assist with any unforeseen problems.

The SITEXCO laser cleaner has been fine-tuned over countless tests to ensure that the wavelength and intensity are perfectly calibrated to clean your anilox rolls. So far, over 400 machines have been sold within the US and Europe, and although the machine is just making its debut within Japan, it holds promise as the eco-friendly laser cleaning machine of the future.

SITEXCO TEG

In 2018, the SITEXCO cleaner received the FTA’s Technology Innovation Award at the annual INFOFLEX convention in the US. This award recognized not only the revolutionary nature of its laser-based cleaning method but also its efficiency, environmental friendliness, and outstanding quality.

Please don’t hesitate to contact us about our eco-friendly laser cleaners.

Contact us