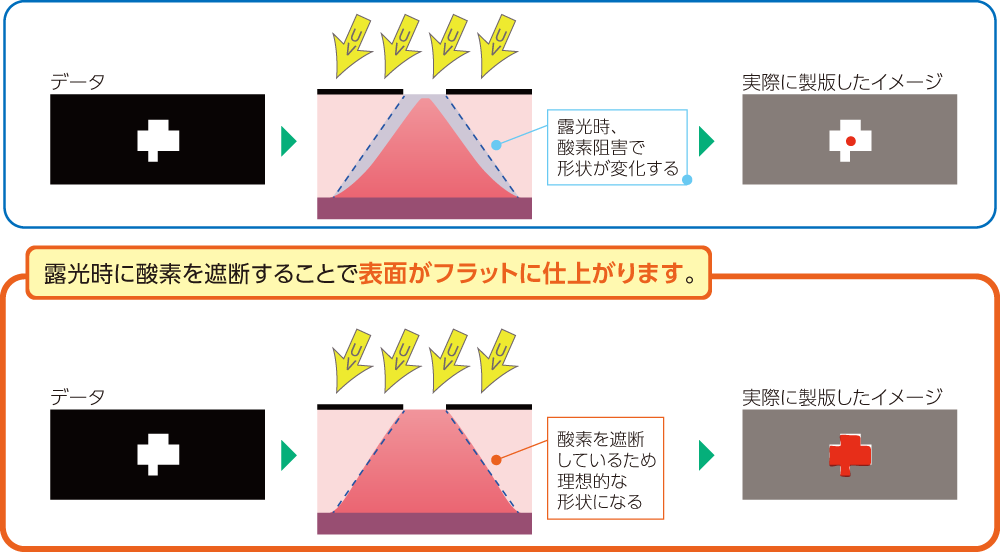

What is a “flat-top”?

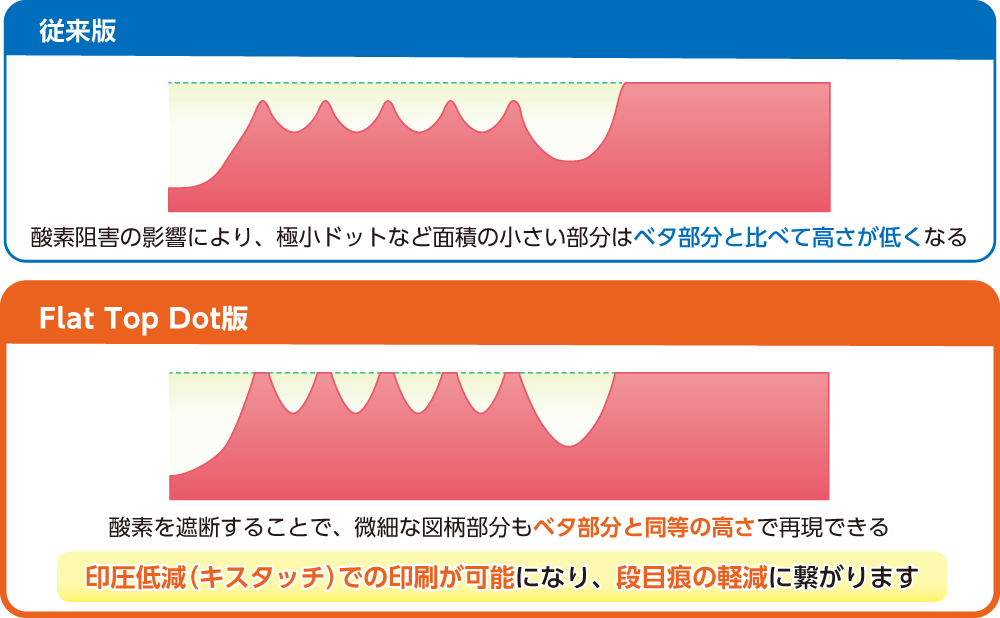

The surface of the resin plate becomes rounded due to the oxygen depletion effect during the curing process. Using flat-top technology however you can maintain a flat surface on the top of the dot through the removal of oxygen.

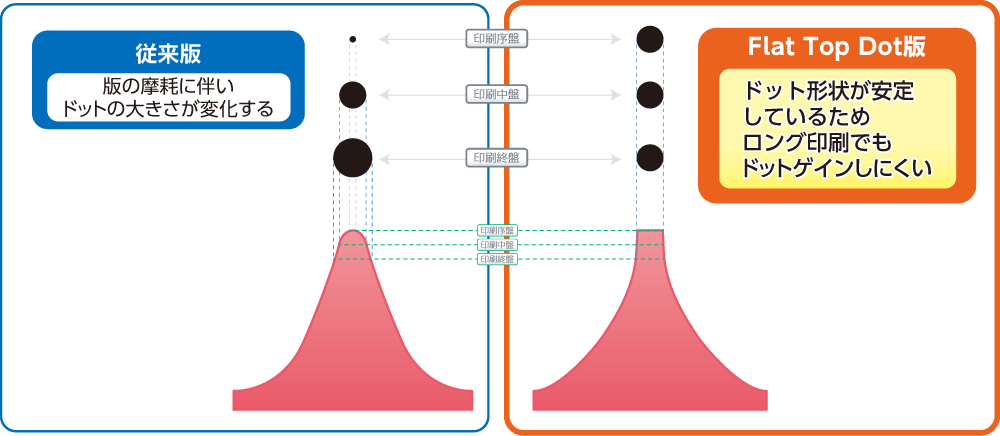

Benefit ① : Reduced dot gain

With a conventional round topped dots, the size of the impression can change over time due to wear on the dot face. On the other hand, flat-top dots have a consistent surface area so they are are more resistant to dot gain over long runs.

Benefit ② : Increased plate durability

Benefit ③ : Reduction of step marks

Due to the oxygen depletion effect, areas of fine plate geometry, such as small dots, can end up forming at a lower height than solids. With flat-top dots however, the procedures accounting for oxygen during the curing process also ensures that the dots form at the desired height. This makes it possible to precisely control the pressure for a kiss touch impression with no step marks.

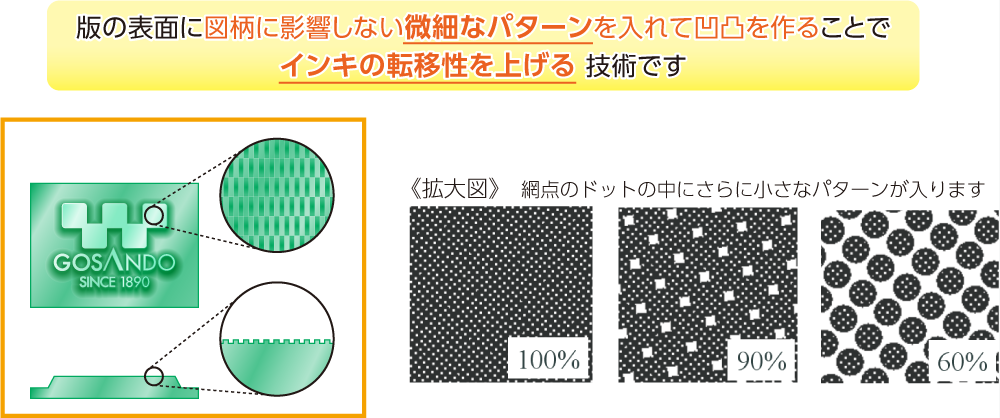

What is a “microcell”?

This technique improves ink transferability by placing a pattern of fine “wells” on the plate face to create an uneven surface which does not otherwise impact the design.

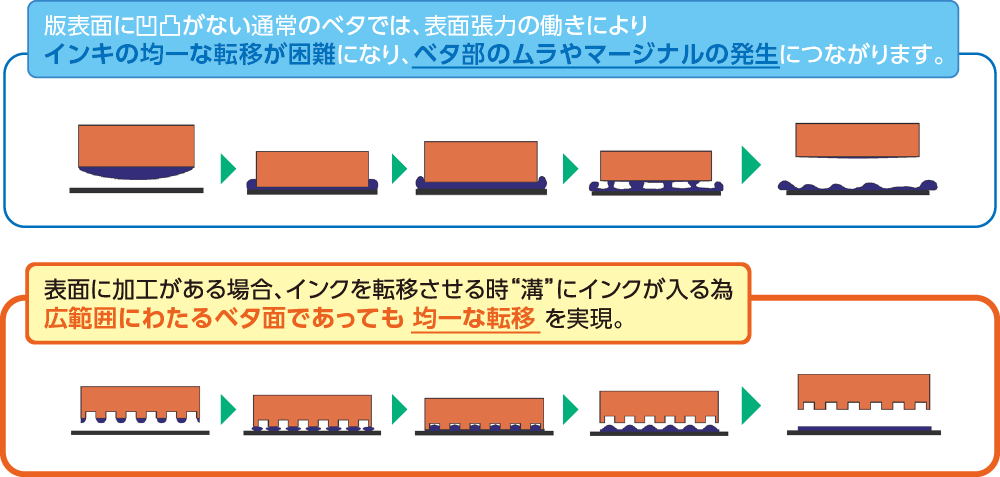

How microcells work

For conventional plates with a flat surface, the effects of surface tension make it hard for ink to transfer evenly, leading to variable results in solid areas along with increased fringing. For surfaces machined with microcells, applied ink will be collected into the “wells” when the plate makes contact, holding the ink in place, and ensuring even coverage.

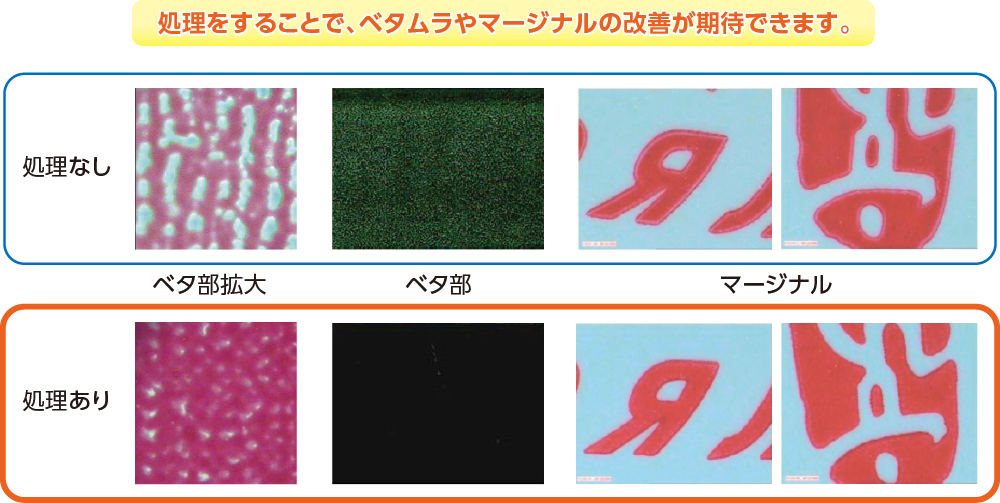

Benefits of microcells

Through this manufacturing technique you can expect to gain more even ink coverage while significantly reducing pinholes and haloing.

About screening

Gradation in flexo printing is expressed the same way as in offset printing, through the use of screening (halftone processing).

The fineness of halftone dots is expressed in terms of “screen ruling” measured in dpi (dots per inch). So, for example, a “25 dpi image” would contain 25 halftone dots within one inch of print, where a higher number means a greater fidelity.

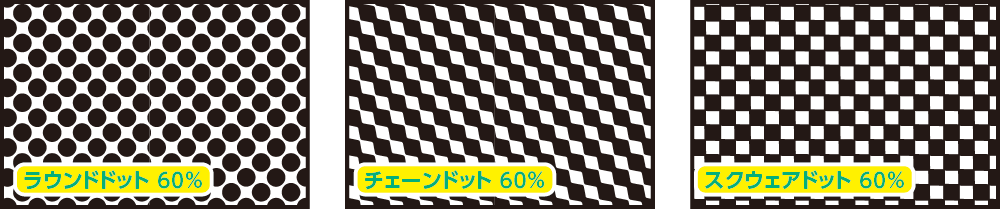

Additionally, there are multiple types of halftone dots which can be selected to match the desired expression.

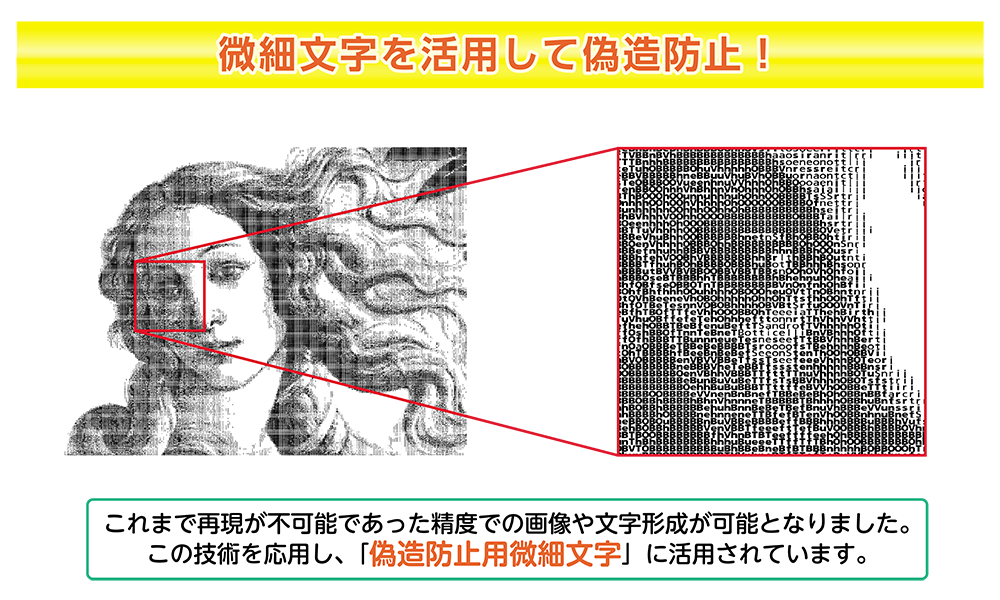

Anti-counterfeiting technology initiatives

We handle everything from package design to plate production for a variety of fields.

In recent years large volumes of Japanese goods have been exported abroad and their popularity will only keep increasing. This popularity comes at a cost however, as many counterfeit Japanese products find their way to market each day.

Our company has many years of experience in flexo plate making and we are working with many manufacturers to develop state-of-the-art anti-counterfeiting technology.

- Minute patterns, not visible to the naked eye, are worked into the plate design

- Treatment with special inks and coatings

- Usage rules are established alongside the owner and print operators to maintain design longevity

Some examples of our efforts: