At Watanabe Gosando, we tirelessly pursue our goal of increasingly exceptional print reproducibility.

We stock a wide range of resin plate materials from both domestic and foreign manufacturers. In flexographic printing, the suitability of different plate materials depends on the application, printing press, and ink. With Watanabe Gosando we take the time to understand your project and print facility’s conditions to ensure that we can provide you with a plate that prints to your exact specifications.

| Plate type | ・Solid photopolymer plates ・Liquid photopolymer plates |

| Compatible thickness | 0.76mm ~ 8.00mm |

| Dimensions | 1,200mm × 2,000mm ※Please contact us if you require a larger size |

| Uses | paper containers / flexible packaging / labels / cardboard / liners / beverage cartons / etc. |

| Compatible inks | We can provide plates for water-based, UV, and solvent inks. |

| Available resins | WP / AFP / TENAFLEX (Japan: Asahi Kasei) Cyrel (America: DuPont) Nyloflex (Germany: XSYS) JemFlex (Japan: Nihon Denshi Seiki) FLEXCEL (America: Miraclon) |

From graphic design workstations to digital flexo plate manufacturing machines, our state-of-the-art digital equipment allow us the flexibility to meet all of your platemaking needs. Our goal is to stand apart from the rest in offering the best digitally manufactured flexo plates on the market.

In addition to specialized plates for water-based inks, we of course also offer plates compatible with UV and solvent inks. In recent years, flexo has come to replace other print methods in a variety of fields such as flexible packaging, folding cartons, and adhesive labels. Our goal is to speedily handle any request, not only for the environmental and productivity benefits, but to continue our legacy as an expert maker of quality plates.

The screen reproduction of our plates is as follows:

- 1.14mm plate, 200 lines

- 1.70mm plate, 175 lines

- 2.54mm plate, 150 lines

- 2.84mm plate, 133 lines

- 7.00mm plate, 80 lines

TENAFLEX-SR

Tenaflex is the latest in liquid photopolymer resins, primarily used for cardboard post-printing. One of it’s notable features is the excellent durability over long print runs. As an added benefit, the material is recognized to not paper dust as easily as other materials. In the past, liquid photopolymer resins had a reputation of low print reproducibility and quickly collecting a lot of paper dust, however remarkable progress has been made over the last decade.

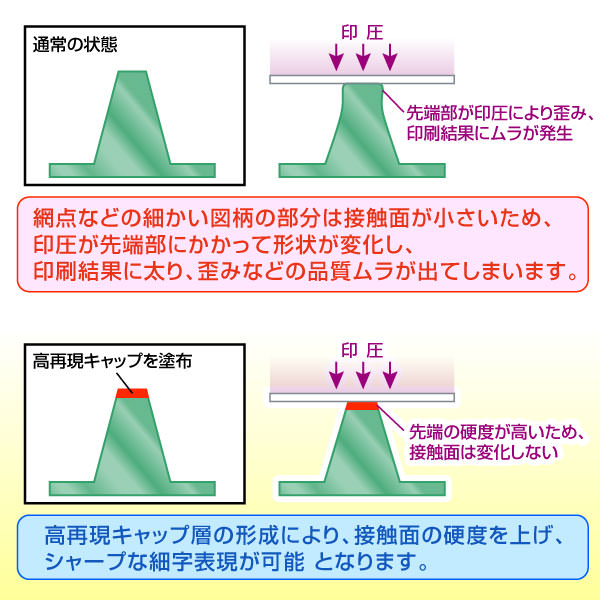

TENAFLEX-SR | High-definition caps

With the addition of a high-definition caps on a TENAFLEX plate, even fine print can be accurately reproduced. This also helps reduce concerns of step lines that can occur with dot printing, allowing you to print both solids and dots with peace of mind. The tradeoff however, is that these high-definition caps cannot be used with thin resin plates, or the overall plate will be too hard to accept ink. Please only use high-definition caps on plates thicker than 5mm.

High-definition cap production process

The hard resin for high-definition caps cannot be applied automatically. Rather, we apply the hard resin to applicable areas (such as halftone dots, fine text, and barcodes) by hand using our own in-house methods and equipment. Since the underlying plate geometry is first made via digital manufacturing, the final image accuracy will not be negatively affected.

AWP

AWP is a flexo plate material that can be washed with water based alkaline cleaners (not fresh water) rather than organic solvents. These resin plates function exceptionally well with UV inks and recently both water and solvent based inks have been successfully used.

AFP

In recent ears Asahi Kasei has also made major strides in their solvent washable flexo plates. These year-by-year improvements have been tailored towards the Japanese printing industry where solvent use is still common. As its quality now surpasses that of European and American solvent plates, AFP has gained attention worldwide.

Cyrel

Hailing from America, DuPont is one of the worlds largest chemical companies and a pioneer in flexo resin plates. In wide use across the world, we have been using Cyrel since it first came to Japan 50 years ago and possess deep insight regarding its capabilities. In recent years DuPont has continued to lead the resin plate revolution with technologies such as EASY Plate – which can produce flat tops and microcells even in less-than-ideal facility conditions – and FAST – which replaces harmful solvents with an efficient thermal process. Their flexo plate making equipment and cleaning solvents are also world standards.

For our part Watanabe Gosando operates 3 lines of DuPont platemaking equipment on a daily basis.

XSYS Nyloflex

The European flexo market has experienced massive growth in recent years. The material with unarguably the highest market share in Europe is XSYS’s XSYS Nyloflex.

In 2025, it will merge with Mac Dermid of the United States to boast the world’s No. 1 market share.

Multiple grades of resin are available for a variety of print media and inks.

In Europe, XSYS’s market share also extends to ink where it is famed as a major player.

We at Watanabe Gosando have been using Nyloflex since it first entered Japan and thus have a wealth of experience regarding the material.

JEMFLEX

This company, headquartered in Japan’s Nara prefecture, manufactures flexo resin plate materials with a focus on corrugated applications. As a domestic manufacturer, their products provide extensive local support and are tailor to the needs of the Japanese market.

FLEXCEL

Originally a division of the American company Kodak, the now independent Miraclon focuses on producing high quality resin plates with high definition and print performance.

The NX system, a laser lithography device, is used to draw images on a special film, which is then used to cure the resin plate.