Flexible Packaging

Our company has learned and honed our craft by studying the European industry, home to the strongest flexo market in the world, and adapting their techniques to suit the Japanese market, with the goal of becoming Japan’s top flexo platemaker.

Flexible packaging uses mainly alcohol-based flexo printing, where quality is dependent on not only the compatibility between the ink and plate material but also that of the plate and substrate.

We navigate these challenges by leveraging our refined skill and years of experience.

【Line Count】100LPI~175LPI

【Material】

| Maker | Plate Material Name | Plate Thickness |

|---|---|---|

| Asahi Kasei | AWP | 1.14 mm / 1.70 mm |

| Asahi Kasei | AFP | 1.14 mm / 1.70 mm |

| DUPONT | CYREL | 1.14 mm / 1.70 mm |

| Miraclon | FLEXCEL | 1.14 mm / 1.70 mm |

Adhesive Labels

The shift to flexo printing in the Japanese market is progressing smoothly not only among large manufacturers but also medium to small companies. Over the years, our company has managed to achieve a remarkable print quality even in fields with some of the most exacting standards, and has been chosen numerous times as the platemaker of choices for Japanese brands sold around the world.

For adhesive labels we mainly use UV ink and focus on ensuring compatibility between the ink and plate material for maximum precision.

【Line Count】120LPI~250LPI

【Material】

| Maker | Plate Material Name | Plate Thickness |

|---|---|---|

| Asahi Kasei | AWP | 1.14 mm / 1.70 mm |

| Asahi Kasei | AFP | 1.14 mm |

| DUPONT | CYREL | 1.14 mm |

| Miraclon | FLEXCEL | 1.14 mm |

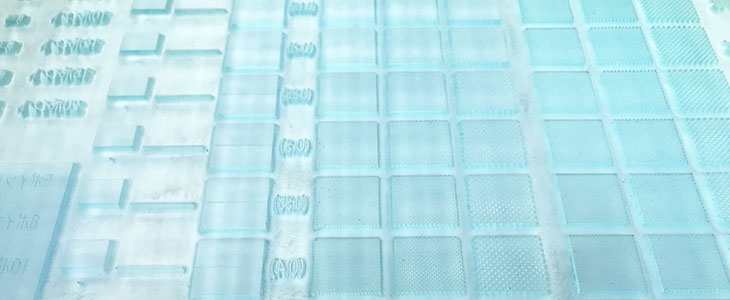

Paper Products

We provide the largest number of resin flexo plates used for printing paper products in all of Japan. UV ink is most commonly used in this application where compatibility between the plate and ink is key.

We provide the largest number of resin flexo plates used for printing paper products in all of Japan. UV ink is most commonly used in this application where compatibility between the plate and ink is key.

Our goal is to create flexo plates which are not only highly accurate in their molding but also reproduce images in exceptional quality through proper color management.

【Line Count】120LPI~200LPI

【Material】

| Maker | Plate Material Name | Plate Thickness |

|---|---|---|

| Asahi Kasei | AWP | 1.14 mm / 1.70 mm |

| Asahi Kasei | AFP | 1.14 mm / 1.70 mm |

| DUPONT | CYREL | 1.14 mm / 1.70 mm |

| Miraclon | FLEXCEL | 1.14 mm / 1.70 mm |

| XSYS | NYLROFLEX | 1.70 mm / 2.30 mm |

Cardboard

Understanding corrugated cardboard printing technology is quite a complicated feat where plate material, substrate, printing machine, and ink all need to be carefully managed. Even using identical materials, print quality can vary drastically depending on the print quality alone.

We will provide the most suitable resin plate tailored to the conditions at your specific print facility.

For more information regarding corrugated printing please see this page.

Sanitary Paper Products

Specialized sanitary paper products such as disposable diapers, facial tissues, and toilet paper rolls which can be difficulty to print using other print methods are often printed flexographically. In Japan we are a trusted source for flexo plates used in this application.

Our goal is to provide resin plates that can overcome common issues such as print fading and excessive paper dust creation by providing plates which can reliable apply ink to uneven surfaces.

【Line Count】50LPI~120LPI

【Material】

| Maker | Plate Material Name | Plate Thickness |

|---|---|---|

| Asahi Kasei | AFP | 1.70 mm / 2.54 mm |

| DUPONT | CYREL | 1.70 mm / 2.54 mm |

| Miraclon | FLEXCEL | 1.70 mm / 2.54 mm |

Construction Materials

Flexo printing is also available for building materials which might be difficult to print on using other methods.

A thick, solvent-resistant resin material will be selected for this application.

Intended materials range from shaped wood and cast resins to PVC objects, all of which typically do not have a flat surface.

This application is used by many production sites in Japan.

【Line Count】30LPI~100LPI

【Material】

| Maker | Plate Material Name | Plate Thickness |

|---|---|---|

| Asahi Kasei | APR | 5.00 mm / 7.00 mm |

| Asahi Kasei | AFP | 5.00 mm |